CIRCLE IMPACT REPORT 2023

PRODUCT.

ECO-DESIGN, OUR PRIORITY

Circularity, sustainability, life cycle, eco-design, eco-design… Since the creation of Circle, these issues have been at the heart of our decisions. In each of our creations, the design, choice of materials and end-of-life optimization are designed to meet the main principles of eco-design and more broadly eco-design. What is eco-design? The eco-design process is a process which takes into account environmental aspects from the design of the product and during all stages of its life cycle, in order to create a product whose impact on the environment is the greatest. low possible.

TO DESIGN A PRODUCT REALLY TAKING ITS ENVIRONMENTAL IMPACT INTO ACCOUNT, IT IS NECESSARY TO CONSIDER IT FROM THE DESIGN PHASE OF THE PROJECT.

How does this eco-design process work? A triple objective, circularity, performance and desirability!

LESS BUT BETTER

A minimalist design so that each material provides real benefit, both technical and environmental. But also, the desire to offer a design which highlights these natural materials and which allows each material to be identified and separated at the end of its life. We always seek to maximize the use of our materials for multiple uses to minimize the number of total materials used. For example, our bras are lined with materials adapted from our Iconic t-shirts.

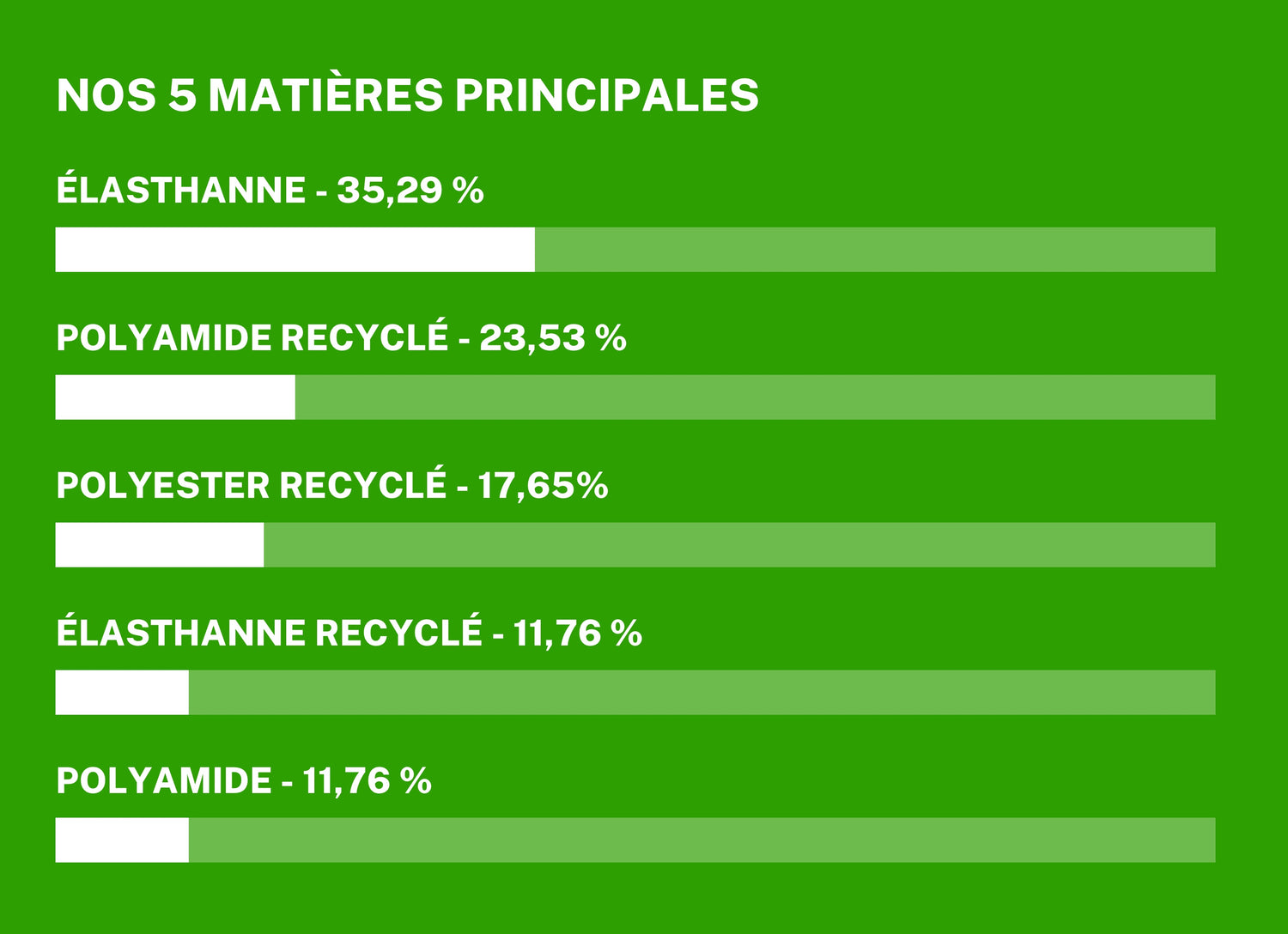

CHOICE OF RAW MATERIALS

Favor the use of materials from natural or recycled resources. From the product design stage, we select materials with low environmental impact. The objective: to meet demanding specifications in terms of performance, quality and ethics. For each material, we analyze and trace the origin of each thread, checking the certifications to ensure that it meets our specifications. We also very often create materials because there are no sufficiently local, natural or recycled and efficient solutions on the market. It's a long process of +18 months, we make no concessions on the quality and durability of our materials.

RECYCLING FIRST

Imagine what the product will become at the end of its life and not just what it will look like at the time of sale. This is the philosophy in which we place ourselves in the creation of each product. Anticipating the durability and end of life of the product from the earliest stages of its design to ensure a low-impact end-of-life plan is essential. We therefore work with several partners with whom we test and analyze each product to test and guarantee durability during development. Finally, the most eco-responsible products are those that last as long as possible. We therefore offer a repair service to extend the life of our clothes.

OUR MATERIALS

Q-NOVA® RECYCLED POLYAMIDE

Recycled polyamide is a recycled synthetic filament, made 100% from pre-consumer nylon waste collected and transformed directly in yarn manufacturing factories in Italy.

The yarn and dye are Oeko tex Standard 100 / Reach / GRS / LCA certified by ICEA.

Environmental impact - Figures in comparison with virgin (non-recycled) polyamide

- - 80% CO2 emissions

- - 90% water consumption

- Mechanical transformation process, no chemicals harmful to humans and the environment

Actions of our fabric supplier who uses Qnova®

- Savings of around 400 tonnes of C02/year.

- An in-house water resource management system helps maintain water consumption at optimal levels

- Reuses 98% of its production

NEWLIFE™ RECYCLED POLYESTER

Recycled polyester is a recycled synthetic filament. It comes 100% from transparent post-consumer plastic bottles, collected in garbage dumpsters 40 km around Turin then mechanically recycled and extruded in Biella in Italy. The yarn and dye are Oeko tex Standard 100 / Reach / GRS / LCA certified by ICEA.

Environmental impact - Figures in comparison with virgin polyester (non-recycled)

- 25 tonnes harvested/h

- - 60% energy consumption

- - 32% CO2 emissions

- - 94% water consumption

- Mechanical transformation process, no chemicals harmful to humans and the environment

Action from our fabric supplier who uses Newlife™

- Participates in the city's water treatment with the Bourgoin-Jallieu water station

ROICA™ ECO SMART RECYCLED ELASTANE

Recycled elastane is a recycled synthetic filament, made from 58% pre-consumer nylon waste collected and transformed in Germany and 42% nylon 6.6 regenerated in Germany. The yarn and dye are certified: Cradle to Cradle Gold Level / Oeko Tex Standard 100 / Reach / GRS.

Environmental impact - Figures in comparison with virgin elastane (non-recycled)

- - 35% CO2 emissions

- - 75% heating energy

- - 64% use of raw raw materials in production

- + 50% recovery of polymer waste in polymerization

- + 90% yarn recovery during spinning

- Mechanical transformation process, no chemicals harmful to humans and the environment

Actions of our fabric supplier who uses Roica™ Eco Smart

- Reduced water consumption by 98%

- Energy reduction of approximately 45%: 460 KW of photovoltaic panels added to solar energy systems.

These sustainable practices are part of our commitment to reducing our ecological footprint and promoting a more environmentally friendly supply chain.

0 %

Made in Europe

All of our products are manufactured locally by our partners in Europe.

0 %

From recycled materials

On average for our products made from recycled materials.

0 %

From materials of natural origin

On average for our products made from materials of natural origin.

0 %

Recyclable and/or biodegradable

All of our products are recyclable and/or biodegradable at the end of their life.

0 K.M.

Traveled on average during the different manufacturing stages

On average, our clothes travel 6 times fewer kilometers before arriving at your home, compared to 45,000 km on average for sports clothing made in Asia.

SUPERNATURAL RUNNER

Efficient, ethical and responsible = 0 compromises.

We couldn't find running shoes that were circular, efficient and aesthetically pleasing to take us where we wanted to go. So we created it. With the SuperNatural Runner our ambition was to create the most environmentally friendly running shoe on a global scale, marking a significant step forward in the sector. It is the first high-performance running shoe, respecting the principles of the circular economy and for the first time manufactured in Europe. Thanks to the use of natural or bio-sourced materials as well as innovative construction methods, the SuperNatural Runner significantly reduces its environmental footprint.

CIRCULAR

Natural and biosourced materials that are highly recyclable or biodegradable, with a construction allowing easy disassembly of these different materials at the end of their life. The top of the shoe is biodegradable and the sole is recyclable while allowing future soles to be made from existing ones.

PERFORMANCE

1 million strides analyzed, 290 grams of performance. The SuperNatural Runner was co-developed with +50 athletes and +5000 kilometers were carried out to analyze each impact and offer a unique sensation over all distances.

LOCAL

Made entirely in Europe with a high quality, ethical and local supply chain.

SUSTAINABLE PARTNERSHIPS

An ecosystem of partners and ambassadors to create, together, the running shoe of the future.

Our in-house technical team worked collaboratively on the development of the shoe's upper, leveraging the performance benefits of Merino wool - such as breathability and odor resistance - to push the innovative nature of the fiber for a shoe high performance racing shoes." John Roberts - Managing Director of The Woolmark Company -

"The running shoe industry is dominated by petroleum-based developments. Circle Sportswear has risen to the challenge with the SuperNatural Runner by offering a responsible alternative without compromising performance. The combination of Lenzing's TENCEL™ Lyocell filament and wool from Woolmark with ProWeave® technology from Coats Footwear opens new possibilities to promote the development of running shoes without synthetic materials" Lenzing AG, Nicole Schram, Director of Global Business Development

CIRCLE IMPACT REPORT 2023

CIRCULAR PERF LAB

OUR NEW MATERIALS

Our ongoing commitment to innovation is to make circularity accessible to everyone. Our technical team is developing new lighter, more resistant, breathable and recycled materials for our products. Working with trusted partners, we are rethinking our production to create high-quality, eco-friendly clothing without sacrificing style, comfort and performance.

NANOTECH™

We have partnered with IMT Mines Albi as part of the “Nanotech” research program to analyze the release of plastic micro/and nanoparticles from our clothes during a washing cycle. The objective was to evaluate the impact of our products and find solutions against the release of microplastics during the washing cycle.

PLNT-FOAM™

INNOVATION AT THE SERVICE OF CIRCULARITY

For the sole of the SuperNatural Runner, we have developed a new innovative PLANTFOAMTM foam created partially from castor beans in partnership with Arkema.

NANOTECH™

We have partnered with IMT Mines Albi as part of the “Nanotech” research program to analyze the release of plastic micro and/or nanoparticles from our clothing during a use and washing cycle. The objective is to evaluate the impact of our products in their user life cycle and to fight and find solutions against release.

This problem was exposed at the RAPSODEE laboratory at IMT Mines Albi and at the French Institute of Textiles and Clothing (IFTH) and we were able to evaluate the release of particles on three material references:

- 100% recycled PES fabric used for our One For All shorts

- 49%PES-43%PA mesh used for our Agility t-shirts

- 65% recycled polyamide - 25% Elastane used for all our Get In Shape, Get Shorty or Hit The Road leggings and shorts.

Context analysis

Carrying out particle size measurements by laser diffraction to measure particle size and particle size distribution. This allows the characterization of particles from 10 nm to 3500 μm.

Washing tests

- Ref 1: 100% PES rec fabric + briefs

Foam on the surface / Low variation in obscuration: objects in very small quantities / The sizes cannot be used, however microscopy confirms the presence of fibers and other agglomerates from the textile analyzed.

- Ref 2: Mesh 49% PES rec 43% PA rec - EA rec

Foam on the surface + Cloudy water / Presence of small quantities of objects after 2nd sampling / Elements with the finest diameters: 1 to 2 microns / Elements with average diameters: between 58.3 and 60.9 microns.

- Ref 3: Mesh 65% PA rec - 25% EA

Cloudy water / Presence of small quantities of objects after 2nd sampling / Elements with the finest diameters: 15 microns / Elements with average diameters: between 72 microns.

Results and a hypothesis.

The release is proven and in very small quantities, 5x lower than products made from traditional synthetic fibers, particularly because all of the solvents and products used in manufacturing are ecological. A hypothesis: the more the rate of materials is recycled, the lower the release.

CIRCLE IMPACT REPORT 2023

TRACEABILITY AND TRANSPARENCY

We ensure full traceability and transparency in our supply chain.

Zoé Loevenbruck, production manager - Circle Sportswear

Article 13 of the AGEC law plans to make it mandatory to display certain environmental characteristics of products in order to inform the public by 2026. Although this law does not yet concern small businesses, our commitment to sustainability is at the heart of everything we do. By choosing to collaborate with Fairly Made to carry out Life Cycle Analyzes on our clothing (an evaluation method aimed at quantifying the environmental impacts of a product or service), we analyzed all of our different materials in order to evaluate each of our products and thus guarantee complete traceability, verified by a third party. Through this analysis, we offer our community total transparency on our supply chain and its impact.

0 %

Of our analyzed materials

With its AVC method, Fairly Made analyzed 100% of the materials we use in our different collections.

0

Traceability

Rating given by Fairly Made after analysis of our production chain.

0

Recyclability

Rating given by Fairly Made after analysis of the recycling capacity of our products.

0

Eco-score

The eco-score or PEF (Product Environmental Footprint) awarded by Fairly Made which aims to assess the environmental impacts of our products throughout their life cycle.

TRANSPARENCY AND TRACEABILITY

For you and for us!

Since the creation of Circle Sportswear, we have had 100% traceability on all our products. In other words, we can reconstruct the entire path taken from the raw material to the final making of the garment, including spinning, weaving and dyeing.

We have chosen not to affix labels to Circle clothing but a QR code. It is a passport which presents each stage of manufacturing and which shares the different options at the end of the product's life.

The collaboration with Fairly Made, a true external control, definitively certifies this transparency with a score of 5/5 in traceability. The choice of our suppliers, their proximity and the certifications they hold allows us to have a clear vision of the origin of all the elements that make up our products.

CIRCLE IMPACT REPORT 2023

CERTIFICATIONS

In our quest for transparent and sustainable practices, the certifications of our partners play a central role in guaranteeing the integrity of each stage of the production of our clothing: the cultivation and transformation of the raw material into yarn, the dyeing process or even the making. These certifications cover different aspects of environmental and social responsibility, shaping a holistic view of our operations.

Oeko-Tex Standard 100 - This certification ensures that the final fabric, dyes and finishes are free of substances harmful to our health. It takes into account a wide range of regulated and unregulated substances, including pesticides, carcinogenic dyes and heavy metals.

GRS - Global Recycled Standard - GRS certification measures and certifies the percentage of recycled materials in the fabric (a minimum of 50%) as well as compliance with various environmental and social criteria. Companies must comply with and monitor legal requirements regarding water consumption, energy consumption and greenhouse gas production. It is prohibited to burn waste on site, and legal wastewater regulations must be followed, with a dedicated system for treating wastewater before it is released into waterways. GRS also certifies the prohibition of forced and child labor, discrimination, harassment and abuse, while ensuring worker health and safety, wages, working hours and various social aspects .

Cradle to Cradle Gold Level - With this certification, products are assessed for their environmental and social performance in five critical sustainability categories: health, material reuse, renewable energy management and carbon management, water and social equity. The health category guarantees the absence of harmful substances in the manufacturing of products. Material reuse aims to eliminate the concept of waste by helping to keep products in perpetual cycles of use and reuse. The renewable energy category ensures manufacturing using renewable energy sources. Finally, water management aims to improve the protection of watersheds. The objective of these categories is to certify all of the operations necessary for the manufacture of a product.

Bluesign - This certification guarantees the absence of toxic substances for humans and the environment, optimization of resources and waste management. It meets environmental requirements with a focus on resource efficiency in production and manufacturing, waste treatment, controlled water consumption, chemical use and CO2 emissions. When it comes to social standards, Bluesign certifies the prohibition of forced and child labor, worker health and safety, and gender equality.

Reach - is a standard that controls the use of chemical substances in European industry. The objective is to identify, evaluate and control chemical substances manufactured, imported and placed on the European market.

RESPONSIBLE PACKAGING

Since the creation of Circle Sportswear, we have been committed to the search for low carbon impact solutions and not only on our products. Circle packaging meets our requirements for quality and sustainability, while minimizing their impact.

LOW CARBON IMPACT AND RECYCLABILITY

We strongly believe in using recycled materials to reduce our environmental footprint. Our packaging is entirely recyclable, designed in Europe and made from craft, a natural material. This carefully chosen approach helps minimize our impact on the environment while ensuring the highest quality packaging.

LOCAL PACKAGING

Our commitment to environmentally friendly practices is also reflected in our choice of partners and local provenance. We favor Portugal and France for our packaging, thus considerably reducing our carbon footprint. Our trusted partners, such as Cadica in Italy and Open Eyes in Poland, share our commitment to sustainable solutions.

A DUAL-USE PACKAGING

We believe that each packaging is an opportunity to share our values and our commitment to the environment. This is why we design our packaging for dual use, going beyond its simple function. Each packaging is a communication medium, transmitting a message that reflects our commitments to sustainability.

By adhering to these criteria, we are confident that our packaging will significantly contribute to our sustainability mission, while providing a meaningful brand experience for our customers.

THE MOST ECO-RESPONSIBLE PRODUCT IS THE ONE THAT LASTS THE LONGEST POSSIBLE.

CIRCLE IMPACT REPORT 2023

BACK TO THE FUTURE

OUR COMMITMENT TO CIRCULARITY

The end of product life is one of the most important levers of circularity. When we know that every year the equivalent of the weight of 13 Eiffel Towers ends up in the trash, we had to find a solution. Our goal is to minimize the creation of over-consumption waste. Thanks to our Back To The Future program, find the best solution according to your situation: customization, repair, or recycling!

How is this program structured? What do we do with the clothes once collected?

Upon receipt of our products, our technical team carries out a product evaluation to determine the best alternative. Three distinct solutions are offered to our customers to respond to the different stages of the life of our products.

CUSTOMIZATION

Create a product, a unique look and style while extending the life of your products thanks to Circle badges.

THE REPAIR

Our ambition is to make our products last as long as possible, for you and for the planet. If a product is damaged but repairable, we promise to restore it to extend its life. We have established a partnership with Tilli Paris, a network of 500 expert craftsmen, to set up a complete repair process for all of our products. We have tested and collaborate with carefully selected tailors, all equipped with technical machines suitable for repairing our high-performance products.

How does it work in practice?

- To make a request, go tohttps://circlesportswear.com/pages/reparation-et-interview

- A questionnaire is available to collect everyone's needs

- We offer the best solution for the product. If a repair is necessary, we take care of the entire process to offer a lifetime warranty on all Circle products.

THE RECYCLING

Recycling being an energy-intensive process, it will only arrive as a final solution, if the garment cannot be repaired or upcycled.

Recycling, how does it work?

Each product is tested to determine its recyclable potential. If the material has not lost its strength and performance, our partner transforms it into yarn to make new fabrics. On the contrary, if it cannot be reused, new objects or accessories will be manufactured.

Suivez nos aventures

Actualités, événements, guides & conseils, innovations environnementales, co-design

et circularité. En vous inscrivant, rejoignez le collectif Circle. La newsletter est envoyée

2 à 4 fois par mois, pas plus. On s'y engage.